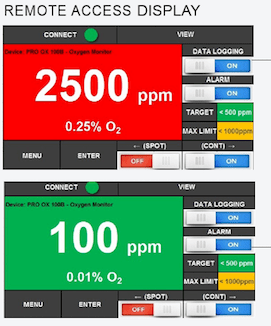

The most advanced and CE approved oxygen monitoring device, the PRO OX-100B not only measures oxygen content down to 100 PPM (0.01%) during the purging process, but is equipped with a Bluetooth transmitting device that allows the oxygen monitor to send the oxygen readings wirelessly to a Bluetooth receivable device, operators may view the readings from a remote location.

Great pride goes into manufacturing the PRO OX-100B in Aquasol Corporation’s ISO Certified Factory in the USA.

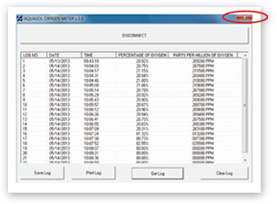

The PRO OX-100B Bluetooth Enabled Programmable Digital Oxygen Monitor’s state-of-the-art technology is patent pending enabling operators to remotely log unlimited amounts of data. Users simply pair the device with the App / Software and use the on-screen menu options. This permits users the ability to access the data interface while standing up to 100 feet (30 meters) away and observe real time data recordings.

The intelligent Color Notification Signal System displays red, amber and green for a quick visual on operator set parameters. Operators will have the access to an easy-to-use App that will track an unlimited amount of data points. Data collected from the oxygen monitor can then be stored for an indefinite period to meet the strictest quality control requirements of nuclear and other highly regulated industries.

The most advanced and CE approved oxygen monitoring device, the PRO OX-100B not only measures oxygen content down to 100 PPM (0.01%) during the purging process, but is equipped with a Bluetooth transmitting device that allows the oxygen monitor to send the oxygen readings wirelessly to a Bluetooth receivable device, operators may view the readings from a remote location. Great pride goes into manufacturing the PRO OX-100B in Aquasol Corporation’s ISO Certified Factory in the USA.

Bluetooth Transmitting Capabilities

• Real Time Recording of UNLIMITED Data

• The PRO OX-100B comes equipped with a Bluetooth transmitting device that allows the oxygen monitor to send the oxygen readings wirelessly to a Bluetooth receivable device with a Windows 10 operating system, allowing the operator to view the readings from a remote location. This permits users with the ability to access the data interface while standing up to 100 feet (30 meters) away.

Unlimited Data Logging Capabilities in Real Time

• With the PRO OX-100B you will be able to create permanent records of UNLIMITED real time data (at 7 second intervals) of oxygen levels for critical welding operations.

Intelligent Color Notification System

• This smart system displays red, amber and green for a quick visual on operator set parameters. The traffic light’s universal appearance is easy and quick for operators and inspectors to understand, reducing the chance of error.

• Eliminate guesswork as Alarms can be set to desired O2 PPM value

• Acceptable oxygen levels can be customized to the user specifications.

CONTINUOUS:

Self Calibrated Model:

Calibrates using ambient air. No special calibration gas required.

2 Point Calibration Model:

Calibrates using ambient air and 99.999% Argon.

Programmable in four popular languages to satisfy international customer needs

Self-Calibrating Model:

Installing the Neoprene Extension Tubing:

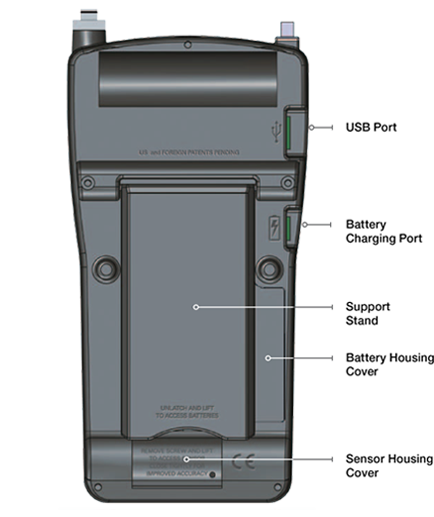

1. Attach neoprene extension tubing with female fitting to the Quick Connect “male” fitting on the top right side of the unit

2. Pull gently to ensure the connection is securely in place

3. Insert the stainless steel probe to the end of the neoprene tube without a fitting

4. Before taking an oxygen measurement, ascertain both connections are tightly secured

To Set Language:

1. Press and hold the “MENU” button

2. Next press the “RIGHT” → button until you see “SETUP: LANGUAGE” displayed

3. Press the “ENTER” button to select language setup

4. Choose the preferred language (German, Spanish, Portuguese, English)

5. Press “ENTER” button to Save and Exit

6. Press “MENU” button to return to main screen

To Set Date and Time:

1. Press the “Menu” button to display the “SETUP” menu

2. Select the “SET DT/TM” option by pressing “ENTER”

3. Use the “RIGHT” → and “LEFT” ← arrow buttons to increase or decrease “HOUR”, “MINUTE”, “SECOND”, “MONTH”, and “YEAR” value, using the “ENTER” button to save settings

| Item No | Description | Dimensions | Weight | ||

|---|---|---|---|---|---|

| English (IN) | Metric (MM) | English | Metric | ||

| P-OX/B KIT | PRO OX-100B Oxygen Monitor & Accessories Kit | 11 x 9 x 4 | 279 x 227 x 102 | 4.00 lb | 1814 g |

| P-OX/B KIT Euro | PRO OX-100B Oxygen Monitor & Accessories Kit with European Charger | 11 x 9 x 4 | 279 x 227 x 102 | 4.00 lb | 1814 g |

| P-OX Sensor | PRO OX-100B Oxygen Sensor | 1 x 1 | 21 x 20 | 0.03 lb | 14 g |

| P-OX Batt | PRO OX-100B 9V NiMH Battery | 2 x 1 x 1 | 48 x 26 x 17 | 0.12 lb | 57 g |

| P-OX Charger/US | PRO OX-100B 12V NiMH Battery Charger with US Type Plug | 3 x 2 x 1 | 8 x 60 x 25 | 0.10 lb | 60 g |

| P-OX Charger/EU | PRO OX-100B 12V NiMH Battery Charger with European Type Plug | 3 x 2 x 1 | 8 x 60 x 25 | 0.10 lb | 60 g |

| P-OX USB | PRO OX-100B USB Cable (72″ or 1.8m) | 4 x 4 x 1 | 102 x 102 x 25 | 0.11 lb | 50 g |

Sensors are available for purchase. Each sensor has a one year warranty. It is not recommended to keep stock of extra sensors. Sensors are readily available to ship and are lightweight.

High-frequency may be an issue with monitors receiving readings around specific welding machines. To test for this, place a piece of metal foil/sheet metal between the monitor and the machine, to protect it from interfering with the circuit board. If the monitor reading is normal, high-frequency equipment is interfering.

Any new 9V rechargeable battery can be substituted in the PRO-OX 100. The specification for the 9V battery is NiMH 280mAh. Additionally, any ordinary (non-chargeable) battery may be used as well.

Battery Life in Continuous Mode:

The PRO OX-100 With a full charge, the battery can supply continuous power for up to 2 1/2 hours.

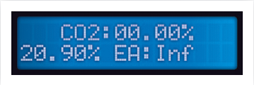

Self Calibrating Model:

Ensure the sensor is plugged into the sockets properly. After running for 30 seconds, if calibration is successful, the screen will display “CALIBRATION DONE”.

Self Calibrating & 2 Point Calibration Models:

If CAL ERR is displayed, sensor must be replaced. Call Aquasol customer service.

The keypad is damaged if the keys do not correspond with what is on the display. The unit must be sent to Aquasol Corporation for repair. Contact customer service for an RGA authorization.

If strange symbols appear on the screen when the toggle switch is in the ON position, the display is damaged.

The unit must be repaired. Contact customer service for an RGA authorization

If there is no display when the toggle switch is in the ON position, either the battery is drained or the LCD is damaged.

If the battery is drained, simply recharge the battery or use the standalone power supply. Refer to section 1.2.2B of the PRO OX-100B manual for instructions.

If the screen does not light up, replace the battery.

If the LCD is damaged, the unit must be sent to Aquasol Corporation for repair. Contact customer service for an RGA authorization.

If there is an issue starting the pump when pressing the SPOT or CONT button, the pump may be damaged. Contact customer service for an RGA authorization.

If the Bluetooth software cannot find the Bluetooth monitor, check to ensure your PRO OX is on and properly charged. Ensure that your computer has a BLE received (Bluetooth Low Energy). BLE must be 4.0 or higher. If not, a Bluetooth adapter must be purchased. Bluetooth software only operates on Windows 10. You may download the Bluetooth software here.

The sensor has a lifespan of approximately one year under normal operating conditions (see manual for operating temperature, proper storage guidelines, etc.).

The PRO OX-100B can operate in temperatures as low as 0°C (32°F) and as high as 50°C (122°F)

When using the Pro OX®-100B Oxygen Monitor for MORE than two (2) continuous hours be sure to turn the power switch to the OFF position. If battery is installed, remove from the housing. Then connect the standalone power supply/charger cable to the port. After this step, connect the power supply/charger plug into the nearest working outlet (110V for US type/220V for EU type). Then simply turn the power switch to the ON position. The Pro OX-100B is capable of operating indefinitely with a standalone power supply.

CAUTION: ALWAYS REMOVE THE BATTERY IF USING THE MONITOR FOR MORE THAN 2 CONTINOUS HOURS. FAILURE TO DO SO CAN OVERHEAT THE BATTERY AND SERIOUSLY DAMAGE THE PRODUCT AS WELL AS VOID THE WARRANTY.

When using The Pro OX-100B Oxygen Monitor for LESS than two (2) continuous hours, ensure a fully charged battery is installed into the battery housing. Then turn the power switch to the ON position. Continue to use the monitor until operation is complete or the battery indicator displays the “low battery indicator”.

The Pro OX-100B is battery operated, but can also be operated through a standalone power supply. For specifications on use, refer to section 2.1.1 of the manual. With a full-charge, the battery can supply continuous power for up to two (2) hours.

Every oxygen monitor is shipped with a Calibration Certificate.

Self Calibrating Model:

If a unit is used very frequently (daily) it should be calibrated once a week. If it is not used frequently, it should be calibrated once every three weeks.

2 Point Calibration Model:

As the unit undergoes 2 point calibration, it is not necessary to recalibrate unless the SENSOR needs replacement. A CAL ERR will indicate a need for replacement.

Self Calibrating Model:

Calibration can be performed on a weekly basis. There are no other specific recommendations regarding maintenance besides general care of the unit such as cleaning, proper storage, etc.

Point Calibration Model:

1. As the unit undergoes 2 point calibration, it is not necessary to recalibrate unless the SENSOR needs replacement. A CAL ERR will indicate a need for replacement.

2. Replace sensor and follow instructions in section 2.1.7 of the manual pages 19-21.

© 2024 Aquasol Corporation. All Right Reserved.