US & FOREIGN PATENTS ISSUED

The revolutionary, patent-pending I-Purge Modular Inflatable Bladder System is the most innovative and versatile pipe purging system available. I-Purge creates an impermeable seal to consume the least amount of purge gas during pipe purging and welding, saving time and money, while achieving consistent, high-quality welds.

Manufactured in the USA, this long-term, reusable bladder system enables operators to satisfy a myriad of purge requirements with one interchangeable solution. The I-Purge comes equipped with several highly advanced features such as its Quick Connect Fittings that snap-in place and allow easy assembly and disassembly of components. The I-Purge also features an extended length, high heat resistant harness that allows the bladders to be placed outside the heat affected zone and can also sufficiently accommodate any pre-heating or high heat applications.

These state-of-the-art features allow the operator to create multiple configurations, including a one sided pipe stopper and a reducer. Bladders are available in sizes ranging from 2 to 70″ (51-1778 mm) and may be purchased either individually or as a complete system, a distinct advantage should additional sizes be desired or a component need replacing.

Ideal for fabrication shops, the I-Purge surpasses existing technology with its advanced design and provides the complete solution for all pipe purging needs.

The revolutionary, patent-pending I-Purge Modular Inflatable Bladder System is the most innovative and versatile pipe purging system available. I-Purge creates an impermeable seal to consume the least amount of purge gas during pipe purging and welding, saving time and money, while achieving consistent, high-quality welds.

BLUE – Inflation of Bladders

Initial function is to inflate bladders then flood weld zone with noble gas

BLACK – Increase Gas Distribution Within Weld Zone

Designed to expedite purging, the secondary (BLACK) purge hose is used to flood the weld zone with inert gas and evacuate oxygen at a faster rate

WHITE – Exhaust Connection

Connect this hose to an Oxygen Monitor, such as Aquasol’s POM®-100B that obtains readings down to 100 PPM (0.01%), for continuous or spot monitoring of oxygen in the weld zone

Make the most out of our modular design!

Convert your I-Purge® two bag systems into one-sided isolators for challenging weld geometry. Both our I-Purge® and I-Purge ®X bladders are convertible with our innovative modular design!

I-Purge® Mod-A Adaptor: A quick connect diffuser for your Mod-A I-Purge® bladder

I-Purge® Mod-B Adaptor: A length of hose with fittings to hook your I-Purge® Mod B bladder to your Argon tank

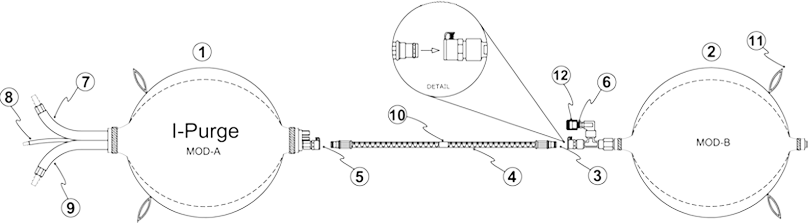

I-Purge Modular System Components: Equipped with the most Advanced Interchangeable Components

1. Module A

2. Module B

3. Quick Connection to Module B

4. Fiberglass High Heat Bridge Harness

9. Inflation & Purge (BLUE) Hose

10. Luminescent Indicator

11. Pull Loops

12. Gas Diffuser

1. Ensure I-Purge is fully assembled (i.e, Modules are securely connected to harness using quick connect fittings).

2. If necessary, connect rope, chain, or wire to the pull loops on the ends of the bladder

modules. This will allow easy insertion and removal of the system.

3. Connect inert gas lines to the BLUE and BLACK hoses.

BLUE gas hose is required to inflate the purge bladders.

BLACK gas hose is optional to expedite the purging process

4. Position the purge unit in the pipe using the luminescent indicator as a guide to center

the system across the root gap

5. Turn the gas supply on to inflate the bladders and purge the weld zone.

Recommended Flow Rates for Purging:

BLUE gas hose should transfer inert gas at 10-32 SCFH (5-15 LPM) for models 2″ – 34″ and 60 SCFH (28.5 LPM) for models 36″– 48″

6. Once a tight seal has been achieved, commence welding while maintaining flow rate.

Recommended Flow Rates During Welding:

BLUE gas hose should transfer inert gas at 15-30 SCFH (7.5-15 LPM)

7. After the weld is complete, turn off the gas supply to deflate the bladders. Once the

heat zone has sufficiently cooled, remove I-Purge from the pipe. Be sure to disconnect

all gas lines and monitoring equipment.

8. Clean I-Purge and store in the provided carrying bag when it is not in use.

| Item No | Dimensions | Standard Harness Length | Description | ||

|---|---|---|---|---|---|

| English | Metric | English | Metric | ||

| ABLD 2 | 2″ | 51 mm | 11″ | 279 mm | 2″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 3 | 3″ | 76 mm | 11″ | 279 mm | 3″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 4 | 4″ | 102 mm | 11″ | 279 mm | 4″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 5 | 5″ | 127 mm | 11″ | 279 mm | 5″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 6 | 6″ | 152 mm | 11″ | 279 mm | 6″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 8 | 8″ | 203 mm | 11″ | 279 mm | 8″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 10 | 10″ | 254 mm | 12″ | 305 mm | 10″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 12 | 12″ | 305 mm | 12″ | 305 mm | 12″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 14 | 14″ | 356 mm | 16″ | 406 mm | 14″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 16 | 16″ | 406 mm | 16″ | 406 mm | 16″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 18 | 18″ | 457 mm | 16″ | 406 mm | 18″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 20 | 20″ | 508 mm | 18″ | 457 mm | 20″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 22 | 22″ | 559 mm | 18″ | 457 mm | 22″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 24 | 24″ | 610 mm | 18″ | 457 mm | 24″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 26 | 26″ | 660 mm | 20″ | 509 mm | 26″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 28 | 28″ | 711 mm | 20″ | 509 mm | 28″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 30 | 30″ | 762 mm | 20″ | 509 mm | 30″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 32 | 32″ | 813 mm | 20″ | 509 mm | 32″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 34 | 34″ | 864 mm | 20″ | 509 mm | 34″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 36 | 36″ | 914 mm | 20″ | 509 mm | 36″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 38 | 38″ | 965 mm | 36″ | 914 mm | 38″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 40 | 40″ | 1016 mm | 36″ | 914 mm | 40″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 42 | 42″ | 1066 mm | 36″ | 914 mm | 42″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 44 | 44″ | 1117 mm | 36″ | 914 mm | 44″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 46 | 46″ | 1168 mm | 42″ | 1067 mm | 46″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 48 | 48″ | 1219 mm | 42″ | 1067 mm | 48″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 50 | 50″ | 1270 mm | 42″ | 1067 mm | 50″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 52 | 52″ | 1321 mm | 42″ | 1067 mm | 52″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 54 | 54″ | 1372 mm | 42″ | 1067 mm | 54″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 56 | 56″ | 1422 mm | 42″ | 1067 mm | 56″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 58 | 58″ | 1473 mm | 42″ | 1067 mm | 58″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 60 | 60″ | 1524 mm | 42″ | 1067 mm | 60″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 62 | 62″ | 1575 mm | 42″ | 1067 mm | 62″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 64 | 64″ | 1626 mm | 42″ | 1067 mm | 64″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 66 | 66″ | 1676 mm | 42″ | 1067 mm | 66″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 68 | 68″ | 1727 mm | 42″ | 1067 mm | 68″ I-Purge Double Purge Bag System with High Heat Harness |

| ABLD 70 | 70″ | 1778 mm | 42″ | 1067 mm | 70″ I-Purge Double Purge Bag System with High Heat Harness |

Modular Components (ABLD-Size-MOD A and ABLD-Size-MOD B)Sold Separately

| Item No | Dimensions | Description | |

|---|---|---|---|

| English | Metric | ||

| ISO 2 | 2" | 51 mm | 2" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 3 | 3" | 76 mm | 3" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 4 | 4" | 102 mm | 4" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 5 | 5" | 127 mm | 5" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 6 | 6" | 152 mm | 6" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 8 | 8" | 203 mm | 8" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 10 | 10" | 254 mm | 10" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 12 | 12" | 305 mm | 12" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 14 | 14" | 356 mm | 14" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 16 | 16" | 406 mm | 16" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 18 | 18" | 457 mm | 18" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 20 | 20" | 508 mm | 20" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 22 | 22" | 559 mm | 22" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 24 | 24" | 610 mm | 24" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 26 | 26" | 660 mm | 26" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 28 | 28" | 711 mm | 28" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 30 | 30" | 762 mm | 30" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 32 | 32" | 813 mm | 32" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 34 | 34" | 864 mm | 34" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 36 | 36" | 914 mm | 36" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 38 | 38" | 965 mm | 38" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 40 | 40" | 1016 mm | 40" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 42 | 42" | 1066 mm | 42" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 44 | 44" | 1117 mm | 44" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 46 | 46" | 1168 mm | 46" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 48 | 48" | 1219 mm | 48" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 50 | 50" | 1270 mm | 50" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 52 | 52" | 1321 mm | 52" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 54 | 54" | 1372 mm | 54" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 56 | 56" | 1422 mm | 56" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 58 | 58" | 1473 mm | 58" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 60 | 60" | 1524 mm | 60" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 62 | 62" | 1575 mm | 62" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 64 | 64" | 1626 mm | 64" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 66 | 66" | 1676 mm | 66" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 68 | 68" | 1727 mm | 68" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| ISO 70 | 70" | 1778 mm | 70" I-Purge Isolator One-Sided Plug with 10' Hose and Valve |

| Item No | Dimensions | Description | |

|---|---|---|---|

| English | Metric | ||

| ABLD-ELH-24 | 24" | 610 mm | 24" (2′) Extended Length High Heat Harness |

| ABLD-ELH-36 | 36" | 914 mm | 36" (3′) Extended Length High Heat Harness |

| ABLD-ELH-48 | 48" | 1219 mm | 48" (4′) Extended Length High Heat Harness |

| ABLD-ELH-72 | 72" | 1828 mm | 72" (6′) Extended Length High Heat Harness |

| ABLD-ELH-CUSTOM | Any Size | Any Size | Custom Lengths Available Upon Request |

| ABLD-CNADP | NA | NA | 1/4" Female MPT to 1/4" Female BSPP Conversion |

I-Purge is designed to fit pipe schedules for each nominal pipe diameter from schedule 5 to schedule 160.

No tools are required when configuring the system. To assemble or disassemble the modules from the harness, simply press on the quick connect fitting at the end of each side of the harness and remove or connect.

The bridge harness is the connecting hose between the two inflatable bladders. It is comprised of a flexible braided fiberglass shielding over a high-heat resistant inner tube.

The central point of the bridge harness is marked with a luminescent indicator to easily align the center of the unit with the root gap. It is important to position the bladders at equal distances from the weld joint to prevent over heating of one side, which could rupture or damage the bladder.

Extended length harnesses offer flexibility to extend placement of the inflatable bladders outside the heat affected zone (HAZ) and to accommodate pre-heating (high-heat) welding applications. Extended length harnesses are available in standard sizes including 12″ (305 mm), 24″ (610 mm), 36″ (914 mm), 48″ (1219 mm) and 72″ (1828 mm). I-Purge sizes 36″ and greater are equipped with a high flow harness to expedite inflation. Custom lengths are available upon request.

To prevent exposure to the HAZ, use an extended length harness appropriate for the situation. These harnesses are sold separately and are available in custom lengths.

I-Purge CAN be used in a pre-heated pipe. For pre-heating and high-heat applications, select an appropriate length of an extended harness to enable placement outside of the heat-affected zone (HAZ).

The outer covering on the inflatable bags of I Purge are the only component which should come into direct contact with the pipe. This material is infused with spark resistant elements which prevent it from catching fire when exposed to sparks and exceedingly hot objects. The outside material of the bladders can withstand temperatures as high as 400°F (205°C). Since the inside of the bladder has a lower heat resistance, it is advisable not to exceed a temperature of 250°F (120°C) for proper operation of the entire system.

I-Purge can accommodate higher temperatures by attaching an extended length harness purchased separately.

I-Purge offers the flexibility of combining modules of different sizes to create a unique configuration. For example, an 8″ (203 mm) module A can be connected to a 4″ (102 mm) module B.

The user MUST NEVER exceed the recommended expansion size labeled on the I-Purge. The unit will not function properly following an over inflation. Refer to manual for details.

If you believe the bladders were overinflated and burst during operation, terminate gas flow immediately. Overinflation can be prevented by adhering to the flow rates listed in the manual. Aquasol does not warrant any overinflation system failures. For more details, review Warranty and System Operation sections of the manual.

I-Purge X and I-Purge (standard) components CANNOT be interchanged. The calibration of the relief valve on I-Purge X is different from the standard I-Purge.

The CE approved I-Purge Modular Inflatable Purge Bladder is manufactured at Aquasol’s ISO Certified factory in the USA under the strictest quality control procedures.

During some applications, the bladder component of the isolator may not be visible, therefore all I Purge Isolator units are equipped with a pressure relief valve to prevent over inflation of the unit. Therefore, a constant supply of gas must be maintained to keep a tight seal on the pipe wall (Refer to Isolator – System Operation).

© 2026 Aquasol Corporation. All Right Reserved.