Every welder knows that it’s important to protect stainless steel welds from oxidation, otherwise they can end up contaminated and susceptible to corrosion. This is commonly done through purging with equipment such as purge dams and inflatable bladders, or by using a backing tape.

Alternative methods are sometimes used to cut back on the expenses associated with purging; however, the savings can be lost through inherent drawbacks these methods often have.

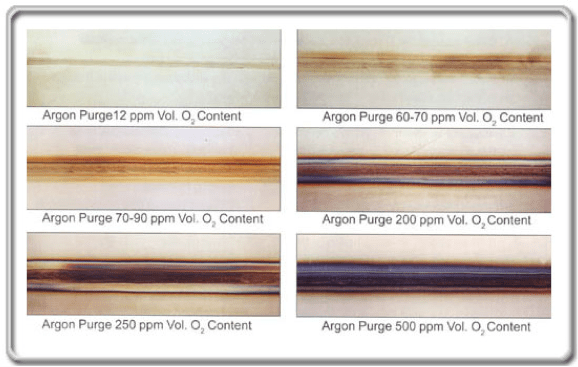

Welds at different levels of oxygen

The worst of these alternatives are “homemade” purge dams constructed out of materials such as cardboard, masking tape and foam. Constructing a homemade dam will take valuable time away from your welders, inevitably produce variable results, and often be a one-time use tool. Additionally, they are a serious fire hazard due to the heat from the welding process, and it is very unlikely they will contain argon as well as professional equipment.

There are other alternative processes that are suitable for certain projects, these include flux and flux coated wire. Flux can be used on small jobs and is quite useful for applications such as sculptures where there are many nonstandard welds. When flux coats the backside of a weld it prevents oxygen from reaching it; however, it leaves slag behind. The slag must be removed via mechanical brushing and solvent, or it could cause pitting and corrosion. For some jobs, the backside may not be accessible after the weld is completed, making it impossible to clean the slag off. In piping, any leftover slag could contaminate the product flowing through the line. This is especially dangerous for any piping that will be used in food production, the slag will contaminate the product while also enabling bacteria to develop.

Flux coated wire, much like flux, is useful for when traditional purging may not be practical. However, this approach will leave behind the same slag as flux powder, and will often allow for oxidation to occur around the weld site.

It is up to the operators to decide what will work for their project, but purging with argon using professional grade equipment such as Aquasol Corporation’s I-Purge inflatable bladders for pipe purging or Fiback fiberglass backing tape for back purging are the best options for a high quality weld.

Check our range of welding products:

© 2025 Aquasol Corporation. All Right Reserved.