Welding and Cutting Journal – EZ Purge Article ar

AQUASOL قناة يوتيوب

AQUASOL شركة:

AQUASOL شركة:

The union of two parts that are usually separate.

The union of two parts that are usually separate.

The thirteenth element on the periodic table, Aluminum is a metallic chemical element that is resistant to corrosion. Aluminum is used in a variety of welding products, including pipes and tapes.

The thirteenth element on the periodic table, Aluminum is a metallic chemical element that is resistant to corrosion. Aluminum is used in a variety of welding products, including pipes and tapes.

The rate at which electrons flow through a current. As the amperage increases, the strength of the electric current also increases. Typically, many weld machines have recommended settings for specific welding applications. Amp selection is a critical part of welding, and may be predicted based on electrode size and composition of the metal being welded. During the back purging process, Aquasol’s Fiback Fiberglass Backing Tape is able to accommodate from 0-600 AMPS. The 200 AMP is ideal for lightweight thinner materials such as aluminum, while the 600 AMP is well suited for dense metals, like carbon and stainless steel which tend to be thicker gauge metals.

The rate at which electrons flow through a current. As the amperage increases, the strength of the electric current also increases. Typically, many weld machines have recommended settings for specific welding applications. Amp selection is a critical part of welding, and may be predicted based on electrode size and composition of the metal being welded. During the back purging process, Aquasol’s Fiback Fiberglass Backing Tape is able to accommodate from 0-600 AMPS. The 200 AMP is ideal for lightweight thinner materials such as aluminum, while the 600 AMP is well suited for dense metals, like carbon and stainless steel which tend to be thicker gauge metals.

American National Standards Institute. The ANSI is a private, non-profit organization that oversees the development of standards for products, services, and systems in the United States.

American National Standards Institute. The ANSI is a private, non-profit organization that oversees the development of standards for products, services, and systems in the United States.

The American Society of Mechanical Engineers. The ASME provides US Navy and Military Codes, including ANSI 31.1, Section III, which states a 1/16" (1.6 mm) minimum gap must be provided during socket welding. Both Aquasol’s SoluGap and SteelSpace Socket Weld Spacer Rings provide this required gap.

The American Society of Mechanical Engineers. The ASME provides US Navy and Military Codes, including ANSI 31.1, Section III, which states a 1/16" (1.6 mm) minimum gap must be provided during socket welding. Both Aquasol’s SoluGap and SteelSpace Socket Weld Spacer Rings provide this required gap.

A weld bead resulting from a back weld pass that is produced after the weld is completed.

A weld bead resulting from a back weld pass that is produced after the weld is completed.

The removal of metals from the opposite side of a joint. This will allow for complete penetration upon welding from that side.

The removal of metals from the opposite side of a joint. This will allow for complete penetration upon welding from that side.

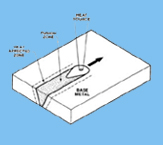

The material that is placed at the root of a weld joint. This is in order to support molten weld metal. Backing materials commonly used include ceramic or a flexible fiberglass tape such as Fiback.

The material that is placed at the root of a weld joint. This is in order to support molten weld metal. Backing materials commonly used include ceramic or a flexible fiberglass tape such as Fiback.

The material that is to be welded.

The material that is to be welded.

The angle of a base metal that meets another surface at any angle, except 90°.

The angle of a base metal that meets another surface at any angle, except 90°.

A weld in a butt joint, which is a type of joint in which the butting ends of one or more work pieces are roughly aligned in the same plane.

A weld in a butt joint, which is a type of joint in which the butting ends of one or more work pieces are roughly aligned in the same plane.

When weld metal completely fills in the entire groove of the joint, fully fusing to the base metal being welded.

When weld metal completely fills in the entire groove of the joint, fully fusing to the base metal being welded.

A distinct fracture-type break that is characterized by a high ratio of length and width to the fracture opening. Cracks can occur when backpurging with ceramic backing tape, as it does not consistently produce a satisfactory weld bead shape, and is prone to create stress points.

A distinct fracture-type break that is characterized by a high ratio of length and width to the fracture opening. Cracks can occur when backpurging with ceramic backing tape, as it does not consistently produce a satisfactory weld bead shape, and is prone to create stress points.

the section of the base adjacent to the weld zone whose structure has been altered by heat. When purging it is important to stay out of the HAZ to avoid any damage to EZ Purge water soluble purge dams or I-Purge inflatable bladders.

the section of the base adjacent to the weld zone whose structure has been altered by heat. When purging it is important to stay out of the HAZ to avoid any damage to EZ Purge water soluble purge dams or I-Purge inflatable bladders.

A crack in the weld formed from high temperatures.

A crack in the weld formed from high temperatures.

The first chemical element on the periodic table. It frequently combines with other elements in organic and inorganic compounds. Hydrogen is frequently used with Argon and Nitrogen as a purging gas.

The first chemical element on the periodic table. It frequently combines with other elements in organic and inorganic compounds. Hydrogen is frequently used with Argon and Nitrogen as a purging gas.

Argon, helium mixes and nitrogen are the preferred inert gases used for purging with stainless steel, chromium, etc.

Argon, helium mixes and nitrogen are the preferred inert gases used for purging with stainless steel, chromium, etc.

The temperature of the weld area in between each weld pass of a multi-pass weld.

The temperature of the weld area in between each weld pass of a multi-pass weld.

An area where a point or edge has been or will be joined together with one or more other pieces of material.

An area where a point or edge has been or will be joined together with one or more other pieces of material.

Metal Inert Gas welding

Metal Inert Gas welding

The seventh chemical element on the periodic table. It combines directly with a variety of elements. Nitrogen is typically combined with Helium (He) and is used as an alternative to Argon as a purging gas.

The seventh chemical element on the periodic table. It combines directly with a variety of elements. Nitrogen is typically combined with Helium (He) and is used as an alternative to Argon as a purging gas.

The eighth chemical element on the periodic table. It can easily contaminate welds, creating cracks and major flaws in the weld joint. Purging is meant to eliminate oxygen from the weld zone, replacing it with inert gas that will help keep the weld consistent and pure. If oxygen is present, the strength and color of the weld will not be ideal.

The eighth chemical element on the periodic table. It can easily contaminate welds, creating cracks and major flaws in the weld joint. Purging is meant to eliminate oxygen from the weld zone, replacing it with inert gas that will help keep the weld consistent and pure. If oxygen is present, the strength and color of the weld will not be ideal.

Tiny bubbles on a weld bead which can weaken a weld. This occurs when oxygen isn’t evacuated properly.

Tiny bubbles on a weld bead which can weaken a weld. This occurs when oxygen isn’t evacuated properly.

A specific temperature to which the base material is heated prior to welding. If a pipe is preheated, the operator must move the water soluble EZ Purge dams or I Purge inflatable bladders outside of the HAZ (heat affected zone).

A specific temperature to which the base material is heated prior to welding. If a pipe is preheated, the operator must move the water soluble EZ Purge dams or I Purge inflatable bladders outside of the HAZ (heat affected zone).

The area created by blocking both sides of a pipe and the root gap so oxygen cannot enter and purge gas cannot escape. Aquasol’s inflatable bladder system, I-Purge, and water soluble dams, EZ-Purge, are used to create the purge chamber.

The area created by blocking both sides of a pipe and the root gap so oxygen cannot enter and purge gas cannot escape. Aquasol’s inflatable bladder system, I-Purge, and water soluble dams, EZ-Purge, are used to create the purge chamber.

The removal of any unwanted gas, such as oxygen, from the purge chamber. Typically, a pure inert gas, such as Argon, Argon/Helium etc. is used. The inert gas fills the purge chamber while oxygen exits. Eliminating oxygen will avoid any imperfections in the weld, including air bubbles that can create cracks and other flaws in the weld.

The removal of any unwanted gas, such as oxygen, from the purge chamber. Typically, a pure inert gas, such as Argon, Argon/Helium etc. is used. The inert gas fills the purge chamber while oxygen exits. Eliminating oxygen will avoid any imperfections in the weld, including air bubbles that can create cracks and other flaws in the weld.

An area of separation between the metals to be joined at its junction point. Expensive inert gases can escape from the purge chamber and inversely oxygen can enter it via the root gap. Therefore, it is important that the root gap be contained with tape when purging. Ideally, the tape will have an adhesive free zone, like that of EZ Zone Tape. This is used to seal the root gap, while preventing contamination.

An area of separation between the metals to be joined at its junction point. Expensive inert gases can escape from the purge chamber and inversely oxygen can enter it via the root gap. Therefore, it is important that the root gap be contained with tape when purging. Ideally, the tape will have an adhesive free zone, like that of EZ Zone Tape. This is used to seal the root gap, while preventing contamination.

The first layer of a multi-layer weld. It is the most essential layer, as it is highly prone to cracking.

The first layer of a multi-layer weld. It is the most essential layer, as it is highly prone to cracking.

A protective gas that is used to prevent atmospheric contamination (oxygen, water vapor). Argon, helium mixes and nitrogen are the preferred shielding gases used for purging with stainless steel, chromium, etc.

A protective gas that is used to prevent atmospheric contamination (oxygen, water vapor). Argon, helium mixes and nitrogen are the preferred shielding gases used for purging with stainless steel, chromium, etc.

Shielded Metal Arc Welding

Shielded Metal Arc Welding

A pipe is inserted into a recessed area of a valve or fitting. At the bottom of the socket is the gap, which compensates for expansion when the weld is made. According to ANSI 31.1, Section III, ASME US Navy and Military Codes, a 1/16" minimum gap must be provided between the pipe end and the socket. This gap is required because if the pipe carries hot fluid, differential thermal expansion between the pipe and the fitting may add significant stress to the weld. The weld is then made on the outer surface of the pipe and fitting. Aquasol’s Solugap and SteelSpace provide and maintain the required minimum gap during socket welding.

A pipe is inserted into a recessed area of a valve or fitting. At the bottom of the socket is the gap, which compensates for expansion when the weld is made. According to ANSI 31.1, Section III, ASME US Navy and Military Codes, a 1/16" minimum gap must be provided between the pipe end and the socket. This gap is required because if the pipe carries hot fluid, differential thermal expansion between the pipe and the fitting may add significant stress to the weld. The weld is then made on the outer surface of the pipe and fitting. Aquasol’s Solugap and SteelSpace provide and maintain the required minimum gap during socket welding.

A steel alloy that does not corrode. 316L certified stainless steel in particular is one of the most common marine-grade metals used in the welding industry for its increased resistance to chloride corrosion. Aquasol’s Steelspace socket weld spacer rings are constructed from 316L certified stainless steel.

A steel alloy that does not corrode. 316L certified stainless steel in particular is one of the most common marine-grade metals used in the welding industry for its increased resistance to chloride corrosion. Aquasol’s Steelspace socket weld spacer rings are constructed from 316L certified stainless steel.

An alloy made out of iron and carbon. One major shortcoming in using steel is that it has a high tendency to corrode, and so there have been an assortment of innovations and measures taken to eliminate the corrosion of steel. Stainless steel is an example of steel which is capable of fighting corrosion effectively.

An alloy made out of iron and carbon. One major shortcoming in using steel is that it has a high tendency to corrode, and so there have been an assortment of innovations and measures taken to eliminate the corrosion of steel. Stainless steel is an example of steel which is capable of fighting corrosion effectively.

A weld whose purpose is to hold parts in proper alignment until the final welds are made. Commonly, filler rods are used to maintain alignment. Composed of foreign metals incompatible with the base metals to be welded, welding rods are non-uniform in size and thickness. Filler rods must be tack welded. Removal of the rods requires the use of mechanical grinding or torch cutting, costly and labor intensive methods. Additionally, rods can leave trace elements that can contaminate the weld area.

Made of EPA-approved Aquasol® Water Soluble Board, SoluShimTM allows for maximum flexibility, durability, and compatibility with any metal. Uniform in size and thickness, SoluShimTM guarantees that the required root gap is maintained throughout the entire welding fit-up. SoluShim™ will begin dissolving instantly with water, allowing the sticks to be easily pulled out of the welding fit up, leaving behind no harmful residue.

A weld whose purpose is to hold parts in proper alignment until the final welds are made. Commonly, filler rods are used to maintain alignment. Composed of foreign metals incompatible with the base metals to be welded, welding rods are non-uniform in size and thickness. Filler rods must be tack welded. Removal of the rods requires the use of mechanical grinding or torch cutting, costly and labor intensive methods. Additionally, rods can leave trace elements that can contaminate the weld area.

Made of EPA-approved Aquasol® Water Soluble Board, SoluShimTM allows for maximum flexibility, durability, and compatibility with any metal. Uniform in size and thickness, SoluShimTM guarantees that the required root gap is maintained throughout the entire welding fit-up. SoluShim™ will begin dissolving instantly with water, allowing the sticks to be easily pulled out of the welding fit up, leaving behind no harmful residue.

Tungsten Inert Gas Welding

Tungsten Inert Gas Welding

The unification of a metal or nonmetals by the application of heat or pressure.

The unification of a metal or nonmetals by the application of heat or pressure.

The metal that remains in the joint. The bead usually has a consistent pattern and can range in color, depending upon the exposure to oxygen.

The metal that remains in the joint. The bead usually has a consistent pattern and can range in color, depending upon the exposure to oxygen.

The molten metal in a weld before it solidifies.

The molten metal in a weld before it solidifies.

The point at which the back of the weld crosses the surfaces of the base metal.

The point at which the back of the weld crosses the surfaces of the base metal.

A structure of straightened filler metal that does not conduct a welding current.

A structure of straightened filler metal that does not conduct a welding current.

The rate at which wire is consumed in welding.

The rate at which wire is consumed in welding.