US & FOREIGN PATENTS ISSUED & PENDING

Patented and practical, EZ Purge is a pre-formed, self-adhesive purge dam that enables operators to save time on weld preparation and improve overall project timeliness. EZ Purge has tapered side walls to fit a variety of pipe schedules and its flat design enables equal distribution of gases across the body of the dam.

Uniquely engineered, EZ Purge comes equipped with EPA approved ZAP® (Zero Air Permeability) technology that maximizes gas retention and reduces gas expenditures. This water soluble purge dam is comprised of Aquasol® Water Soluble Paper and is 100% biodegradable and environmentally friendly. EZ Purge rapidly dissolves, leaving behind no residue in the pipeline.

EZ Purge saves valuable labor hours on dam construction and is easy to use. The operator simply peels, inserts, and presses the purge dam into place. No other product available on the market today can provide such a reliable, efficient, and environmentally sound solution to your pipe purging needs.

* or distance recommended by Project Engineer

| Pipe Size | Recommended Distance | ||

|---|---|---|---|

| English | Metric | English | Metric |

| 2″ – 8″ | 51 – 203 mm | 6″ | 152 mm |

| 10″ – 22″ | 254 – 559 mm | 8″ | 203 mm |

| 24″ – 36″ | 610 – 914 mm | 12″ | 305 mm |

| 40″+ | 1 m+ | 24″ | 610 mm |

Before beginning the purging process, clean inner walls of pipe

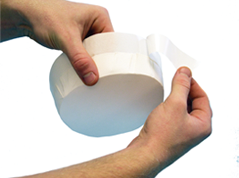

Peel liner off outer circumference of dam to fully expose adhesive, keeping it away from contaminants and debris

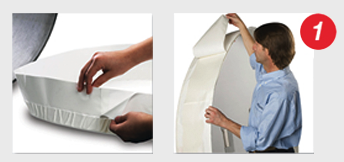

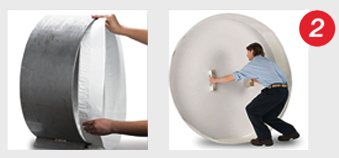

Align adhesive edges to the inside pipe wall and insert dam to desired location. (See Recommended Proximity to Weld Joint Chart)

Thoroughly press adhesive on circumference of dam along inside of pipe wall to create even seal

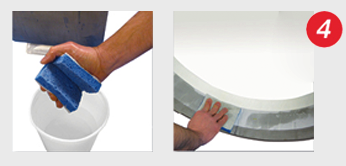

Moisten an ordinary sponge with water, squeeze out excess water until sponge is damp. Lightly dab sponge along Aquasol Water Soluble Tape portion of dam. The dampened sponge will reactivate the adhesive to ensure zero air permeability.

For Sizes above 56” (1422 mm), inquire for directions.

| Item No | Pipe Diameter | case pack | |

|---|---|---|---|

| English | Metric | ||

| EZP-.50 | 1/2″ | 13 mm | 1000 |

| EZP-.75 | 3/4″ | 19 mm | 1000 |

| EZP-1.0 | 1″ | 25 mm | 1000 |

| EZP-1.25 | 1 1/4″ | 32 mm | 1000 |

| EZP-1.50 | 1 1/2″ | 38 mm | 1000 |

| EZP-2.0 | 2″ | 51 mm | 1000 |

| EZP-2.5 | 2 1/2″ | 63 mm | 1000 |

| EZP-3.0 | 3″ | 76 mm | 1000 |

| Item No | Pipe Diameter | case pack* | |

|---|---|---|---|

| English | Metric | ||

| EZP-2 | 2″ | 51 mm | 192 |

| EZP-2.5** | 2 1/2″ | 63 mm | 192 |

| EZP-3 | 3″ | 76 mm | 192 |

| EZP-4 | 4″ | 102 mm | 48 |

| EZP-5 | 5″ | 127 mm | 48 |

| EZP-6 | 6″ | 152 mm | 48 |

| EZP-8 | 8″ | 203 mm | 48 |

| EZP-10 | 10″ | 254 mm | 48 |

| EZP-12 | 12″ | 305 mm | 48 |

| EZP-14 | 14″ | 356 mm | 24 |

| EZP-16 | 16″ | 406 mm | 24 |

| EZP-18 | 18″ | 457 mm | 24 |

| EZP-20 | 20″ | 508 mm | 24 |

| EZP-22 | 22″ | 559 mm | 24 |

| EZP-24 | 24″ | 610 mm | 24 |

| EZP-26 | 26″ | 660 mm | 24 |

| EZP-28 | 28″ | 711 mm | 24 |

| EZP-30 | 30″ | 762 mm | 24 |

| EZP-32 | 32″ | 813 mm | 24 |

| EZP-36 | 36″ | 914 mm | 24 |

| EZP-40 | 40″ | 1016 mm | 10 |

| EZP-42 | 42″ | 1067 mm | 10 |

| EZP-44 | 44″ | 1118 mm | 10 |

| EZP-48 | 48″ | 1219 mm | 10 |

| EZP-52 | 52″ | 1321 mm | 10 |

| EZP-56 | 56″ | 1422 mm | 10 |

| EZP-60 | 60″ | 1524 mm | 10 |

| EZP-64 | 64″ | 1626 mm | 10 |

| EZP-72 | 72″ | 1829 mm | 10 |

| EZP-84 | 84″ | 2134 mm | 10 |

*Sold in full or half case quantities **Custom sizes available upon request

*Sold in full or half case quantities

**Custom sizes available upon request

EZ Purge is used in various industries including off-shore oil rigs, refineries, fossil fuel plants, breweries, shipbuilding, processing plants (food, dairy, beverage, pharmaceutical), nuclear power plants, government and military, power plants, petrochemical plants, water treatments plants and much more.

EZ Purge has a shelf life of approximately one year. To increase shelf life, store EZ Purge in a dark, cool and humidity controlled environment. Ideal storage temperature is 70°F with approximately 50% humidity. EZ Purge should always be stored in the water proof package that is included with purchase. Contact with water must be avoided at all times. For easy reference, the manufacturing date is labeled on the bottom of each EZ Purge box.

If the water soluble EZ Purge dam tears accidentally during installation, simply cover torn spot with Aquasol® Water Soluble Tape.

It takes approximately 5 minutes for the EZ Purge adhesive liner to dry after being dampened for application.

If the size of EZ Purge does not exactly match the size of the pipe, it is easy to alter the dam to create the perfect desired fit. Simply cut the tape portion of dam as it is being inserted. Then overlap the cut ends to create the desired size. Repeat if necessary. If the pipe ID is slightly too big for the specific EZ Purge size, additional Aquasol® Water Soluble Tape can be added to reinforce the seal along the pipe wall.

The EZ Purge adhesive is engineered in such a way that it will not inhibit the user from placing the dam in proper position. The strength of the “tack” or stickiness of the adhesive allows the user to have control and reposition the dam if not properly placed on the first attempt.

To reposition EZ Purge, carefully remove the tape portion of dam from the sidewall of the pipe. Then move it to the desired location and apply additional Aquasol® Water Soluble Tape for reinforcement, if required

If the water soluble tape becomes dry, lightly moisten it with a dampened cloth or foam brush. The adhesive will be reactivated instantaneously. Be careful not to saturate the cloth as the tape will dissolve.

To create a tight seal, first ensure the surface of the inner pipe has been cleaned and that no oils remain. This will increase the integrity of the seal. Once the dam is correctly positioned, the dam can be secured in place by introducing moisture to reactivate the adhesive and form a tight seal. Please note, it is recommended to use a lightly moistened sponge, and not a dripping sponge. Too much moisture will cause the paper and tape adhesive to start to dissolve.

For more information, please refer to our video at http://www.youtube.com/watch?v=77smUxzdDg8 minute marker 9:17.

EZ Purge is made from Aquasol® Water Soluble Paper, which has a flash point of 450°F (232°C).

When welding, the EZ Purge dams must be placed far enough from the root gap so that the heat affected zone (HAZ) does not char or degrade the paper’s water soluble properties.

Recommend distances for placing EZ Purge from the root gap are listed below. These distances depend on the pipe diameter size (ID) or the recommended distance provided by the project engineer to move out of the HAZ.

| Pipe Size | Recommended Distance (English) |

Recommended Distance (Metric) |

|---|---|---|

| 2 – 8″ | 6″ | 152 mm |

| 10 – 22″ | 8″ | 203 mm |

| 24 – 36″ | 12″ | 305 mm |

| 40″+ | 24″ | 610 mm |

Aquasol® Water Soluble Products, including EZ Purge® Water Soluble Purge Dams, must be flushed with an aqueous solution or steam in order to dissolve. Contact Aquasol Corporation for further information.

© 2026 Aquasol Corporation. All Right Reserved.