The Opti-Purge Inflatable Purging System increases productivity when welding large diameter pipes 48″ to 84″ (1219 mm to 2133 mm) of various materials including stainless steel, titanium, nickel and several other metals and alloys.

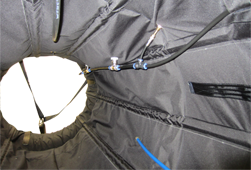

The unique one-piece design of Opti-Purge consists of two outer rings and a hollow connector. The unit is easily and quickly inflated to create an impermeable seal within the pipe wall. The hollow connector dramatically reduces the amount of inert gas needed to purge the weld zone, saving both time and money. The exterior of the hollow connector consists of high heat resistant material that can be exposed to temperatures up to 1004°F (540°C).

A reflective strip on the hollow connector conveniently indicates the center of the Opti-Purge, allowing for fast and accurate alignment of the system.

The Opti-Purge is the ideal solution for welding large pipe rapidly, requiring minimal preparation for maximum results.

The Opti-Purge Inflatable Purging System increases productivity when welding large diameter pipes 48” to 84” (1219 mm to 2133 mm) of various materials including stainless steel, titanium, nickel and several other metals and alloys. The unique one-piece design of Opti-Purge consists of two outer rings and a hollow connector. The unit is easily and quickly inflated to create an impermeable seal within the pipe wall. The hollow connector dramatically reduces the amount of inert gas needed to purge the weld zone, saving both time and money. The exterior of the hollow connector consists of high heat resistant material that can be exposed to temperatures up to 1004°F (540°C).

Multiple inlet/exhaust ports for faster, more efficient purging

BLUE – Inflation of unit

Initial function is to inflate the unit by allowing gas to flow into the internal tubing system. Then it proceeds to flood the weld zone with noble gas.

BLACK – Increase Gas Distribution Within Weld Zone

Designed to expedite purging, the secondary (BLACK) purge hose is used to flood the weld zone with inert gas and evacuate oxygen at a faster rate

WHITE – Exhaust Connection

Connect this hose to an Oxygen Monitor, such as Aquasol’s PRO OX®-100 that obtains readings down to 100 PPM (0.01%), for continuous or spot monitoring of oxygen in the weld zone

1. Using the pull loops, position Opti-Purge in the pipe so that the reflective, glow tape portion in the center of the unit is aligned with the root gap

2. Connect inert gas lines to the BLUE and BLACK hoses

BLUE gas hose is required to inflate the purge bladders

BLACK gas hose is optional to expedite the purging process

3. Turn the gas supply on to inflate the unit and purge the weld zone

Recommended Flow Rate for Purging:

150 CFH (70 LPM)

4. Once a tight seal has been achieved, commence welding while maintaining flow rate

5. After the weld is complete, turn off the gas supply to deflate the unit. Once the

heat zone has sufficiently cooled, remove Opti-Purge from the pipe. Be sure to disconnect

all gas lines and monitoring equipment.

6. Clean Opti-Purge and store in area away from hazardous and sharp objects

Standard sizes of Opti-Purge range from 48″ (1219 mm) to 84″ (2133 mm).

Inquire for more information.

If you believe Opti-Purge has been overinflated and burst during operation, terminate gas flow immediately. Overinflation can be prevented by adhering to the recommended flow rate referred to in the manual. Aquasol does not warrant any overinflation system failures. For more details, review Warranty and System Operation sections of the manual.

No tools are required when configuring the Opti-Purge system. Simply connect the appropriate gas lines as needed and in accordance with the manual.

The outer covering on the hollow connector of the Opti-Purge consists of a high heat resistant, durable fabric that can be exposed to temperatures up to 1004°F (540°C) to accommodate the heat affected zone (HAZ).

To ensure consistently pure welds when using Opti-Purge, keep the purge bladder off the ground and away from contaminants and sharp objects. It is important to keep Opti-Purge free of dirt and debris which may compromise the weld quality. Store in box provided or a protective bag when not in use.

© 2024 Aquasol Corporation. All Right Reserved.