US & FOREIGN PATENTS PENDING

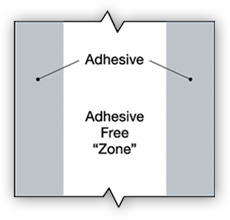

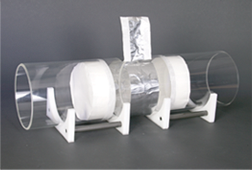

EZ Zone® tape is the perfect, innovative solution for preventing weld seam contamination by sealing the root gap between two pipes and retaining the argon gas. The tape consists of two adhesive-coated aluminum strips on the outer edges and an adhesive-free area in the middle.

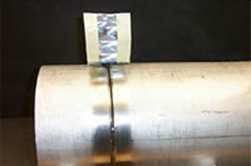

Due to its unique construction, the edges of the aluminum tape adhere to both sides of the root gap of stainless steel and aluminum pipes, while the adhesive-free area is placed directly over the gap. The adhesive never comes into contact with the weld area during welding, resulting in a clean, contamination-free weld seam.

The EZ Zone adhesive tape is free of halogens and fluorocarbons, and consists of aluminum foil with a thickness of 74 micrometers, which adapts optimally to irregular surfaces and is heat-resistant up to 260 °C.

With the EZ Zone tape, the welder can effectively prevent contamination in the weld pool and thus produce more defect-free welds. This advantage made the adhesive tape the standard in the atomic energy sector, the chemical industry, in conventional power plants and in aviation within a very short time.

EZ Zone Tape innovatively offers the perfect solution for preventing weld contamination when sealing the root gap between pipes to retain Argon gas. The welding tape is comprised of two adhesive coated aluminum strips on the outside edges, with an adhesive-free center “Zone.”

Contaminant Free Weld

Flexible & Heat Resistant

High Quality and Safe Components

| PRODUCT | ITEM NO | DESCRIPTION | WIDTH | WIDTH OF THE ADHESIVE-FREE ZONE | LENGTH | |||

|---|---|---|---|---|---|---|---|---|

| ENGLISH | METRIC | ENGLISH | METRIC | ENGLISH | METRIC | |||

| EZ-ZT 2.5 | EZ Zone Tape | 2.5″ | 64 mm | 1″ | 25 mm | 75′ | 23 m | |

| EZ-ZT 4.0 | EZ Zone Tape | 4.0″ | 102 mm | 2″ | 51 mm | 75′ | 23 m | |

EZ Zone Tape offers the perfect solution for preventing weld contamination. The welding tape is composed of two aluminum adhesive areas on the outside edges, with an adhesive-free center “Zone”. The unique design of the aluminum welding tape allows the edges to stick to the area surrounding the root gap on stainless steel and aluminum pipes with the adhesive-free “zone” being placed over the weld. The adhesive portion of the tape never comes in contact with the pipe as it is welded, creating a clean, contaminant-free weld.

The maximum pre-heat temperature of EZ Zone Tape is 500°F (260°C). Please note if applying EZ Zone Tape after the pre-heat temperature is achieved, the adhesive will not bond to the metal surface. In addition, if you apply the EZ Zone Tape before the pre-heat temperature is achieved, the adhesive will “cure” or thermoset to the metal surface and may become difficult to remove.

The minimum application temperature for EZ Zone Tape is 10°F (-12.5°C).

EZ Zone Tape is halogen and fluorocarbon-free, creating a safe work environment.

EZ Zone welding tape has become a standard in the nuclear, chemical power plant, aerospace, and many other advanced welding industries.

© 2024 Aquasol Corporation. All Right Reserved.